Off-Grid Power Solutions for Mining Areas

Technical Advantages of Mobile PV-BESS Fully Automated Stations in Mining

With the rapid development of the global mining industry, remote mining areas are increasingly in need of stable power sources. Traditional diesel generators not only incur high fuel transportation costs and cause severe pollution, but also frequently suffer from downtime due to road blockages or fuel tank maintenance. Mobile solar power units, functioning as "portable solar power stations," are becoming an ideal off-grid power solution for mining operations.

PV + BESS Supports Mining Production

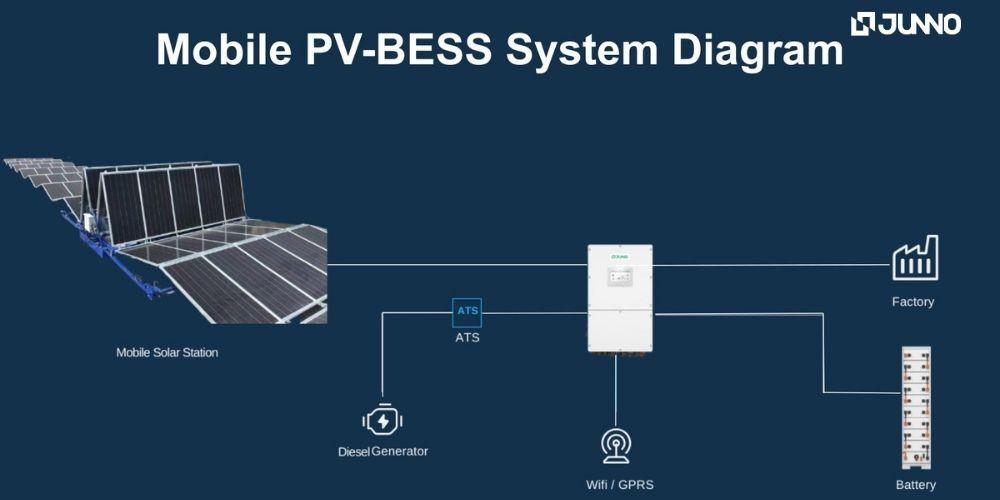

Solar panels convert sunlight into electricity, providing green energy for drilling rigs, crushers, and ore processing equipment. At night and on cloudy days, the energy storage system continues to output to ensure that key processes such as crushing and sorting are not interrupted.

Smart Energy Management Ensures Continuous Operation

The system automatically adjusts the timing of power generation and discharge through real-time monitoring of light and load demand; combined with remote monitoring, the operation and maintenance team can monitor the status of equipment and dispatch power resources at the command center, reducing field inspections.

Modular Design Enables Rapid Deployment

Power cabinets, inverters, and batteries are pre-installed, directly “plug and play.” There is no need to build the foundation; it can be completed in a few hours, with the progress of mining and flexible relocation.

Fully Automated Operation Reduces Labor Costs

Equipped with an 8 kWh battery dedicated to automated opening and closing, the unit requires no manual intervention.

Why Do Mines Choose Mobile PV-BESS Fully Automated Stations?

Enhancing Energy Independence in Off-Grid Mining

Freedom from the high dependence on diesel fuel on roads and weather, underground drainage, ventilation, and mechanical operations can be maintained even during the rainy season, landslides, or snow-clogged mine roads.

Reducing Environmental Impact & Promoting Sustainability

Zero tailpipe emissions, eliminating PM2.5 and noise from diesel engines, and protecting the ecological reserve around the mine. Abandoned mine pits can be transformed into “photovoltaic gardens” to help the ecological restoration of the mining area.

Scalable Capacity Aligns with Mining Needs

As the size of the quarry expands, the power supply capacity can be smoothly increased by simply increasing the number of power generation pods; when a new ore body is temporarily put into operation or overhauled, the mobile optical storage power generation pods can also be quickly borrowed to supplement the power supply.

Typical Mining Applications

Arctic Iron Ore Mining

In cold iron mines in Northern Europe and Canada, low-temperature-resistant batteries and bifacial solar panels store sufficient energy before polar nights to support continuous drilling and blasting operations, enduring temperatures as low as –30°C.

Desert Gold Mine Tailings Recovery

The use of sand-proof crystalline glass with an automatic blowing system ensures that the solar panels quickly regain their efficiency after sandstorms. Tailings pumping station and spillway electricity are guaranteed by the solar system throughout the day.

Tropical Bauxite Leaching Operations

In high-humidity environments, the mobile PV-BESS fully automated stations are made of corrosion-resistant steel with built-in dehumidifiers to provide continuous power to the solvent recovery pump room and pipeline heating system, reducing the risk of chemical leakage.

Challenges & Future Prospects

Natural Condition Variability

Alternating rain and sunshine, dusty weather, or extreme nights can affect power generation, and by integrating with micro wind power and modular hydrogen storage systems, diversified energy microgrids can be constructed.

Initial Investment & Maintenance Coordination

Mining companies can share the investment through government subsidies, carbon trading revenues, or the Energy Service Company (ESCO) model to achieve a “zero upfront cost” pilot.

Deep Integration with Smart Mines

With the maturity of IoT, edge computing, and AI operation and maintenance, the digital management of the entire life cycle of the mobile PV-BESS fully automated station can be realized in the future, and the automatic prediction of power generation and consumption curves can further improve reliability and economy.

Conclusion

Under the dual pressures of energy security and environmental protection, mobile PV-BESS fully automated stations are no longer a futuristic concept but a practical tool for the green transformation of mining. As technology evolves and supportive policies improve, they will provide the global mining industry with more stable, efficient, and sustainable off-grid power solutions.